LIGHTWEIGHT AND DURABLE CARBON COMPOSITE STRUCTURE

FROM MATERIALS, DESIGN TO PRODUCTION

Lightweight type 5 CFRP tanks with patented technologies enable higher payloads, lower thermal loss, and flexible in-house production for launch vehicles.

CFRP FOR DIVERSE AEROSPACE APPLICATIONS

With complete in-house capabilities in composite design, manufacturing, and testing, Perigee delivers advanced composite structures for diverse aerospace applications. Simply share your requirements.

CRYO-COMPATIBLE LINERLESS PROPELLANT TANK

Lightweight and high-performance tanks

30% payload increase over aluminum tanks, the optimal choice for small launch vehicles and other aerospace applications.

End-to-End in-house capability

Complete design, development, production, and testing in-house, enabling flexible adaptation to customer needs and timelines.

Proven and certified expertise

ISO 9001:2015 certified with patented technologies, already applied to Blue Whale systems.

THE PRECISION SOLUTION FOR COMPLEX METAL COMPONENTS

Electroforming enables precise, durable metal components with complex geometries, offering cost-efficient mass production for applications from launch vehicles to satellites, aircraft engines, and defense systems.

High Strength and Precision

Electroforming’s cold process maximizes material strength and enables high-precision colling channel structures.

Enhanced Cooling and Efficiency

Excellent surface finish of regenerative cooling channels reduces pressure drop, turbopump power demand, and improving overall engine efficiency.

Cost-efficient & Flexible Production

Cost reduction through a mass-production-compatible electroforming process, with manufacturing capability up to D500/L700 mm without extra facility investment.

Applications

Launch vehicles and satellite propulsion systems

Aircraft engines and cooling systems

Defense and special-purpose equipment

Heat exchangers for nuclear powerplant systems and related equipment

CRYOGENIC PROPELLANT AND HIGH-PRESSURE GAS CONTROL VALVES

Perigee utilizes internally developed cryogenic propellant and high-pressure gas valves in its 3-ton gas generator cycle and 1-ton pressure-fed cycle methane engines.

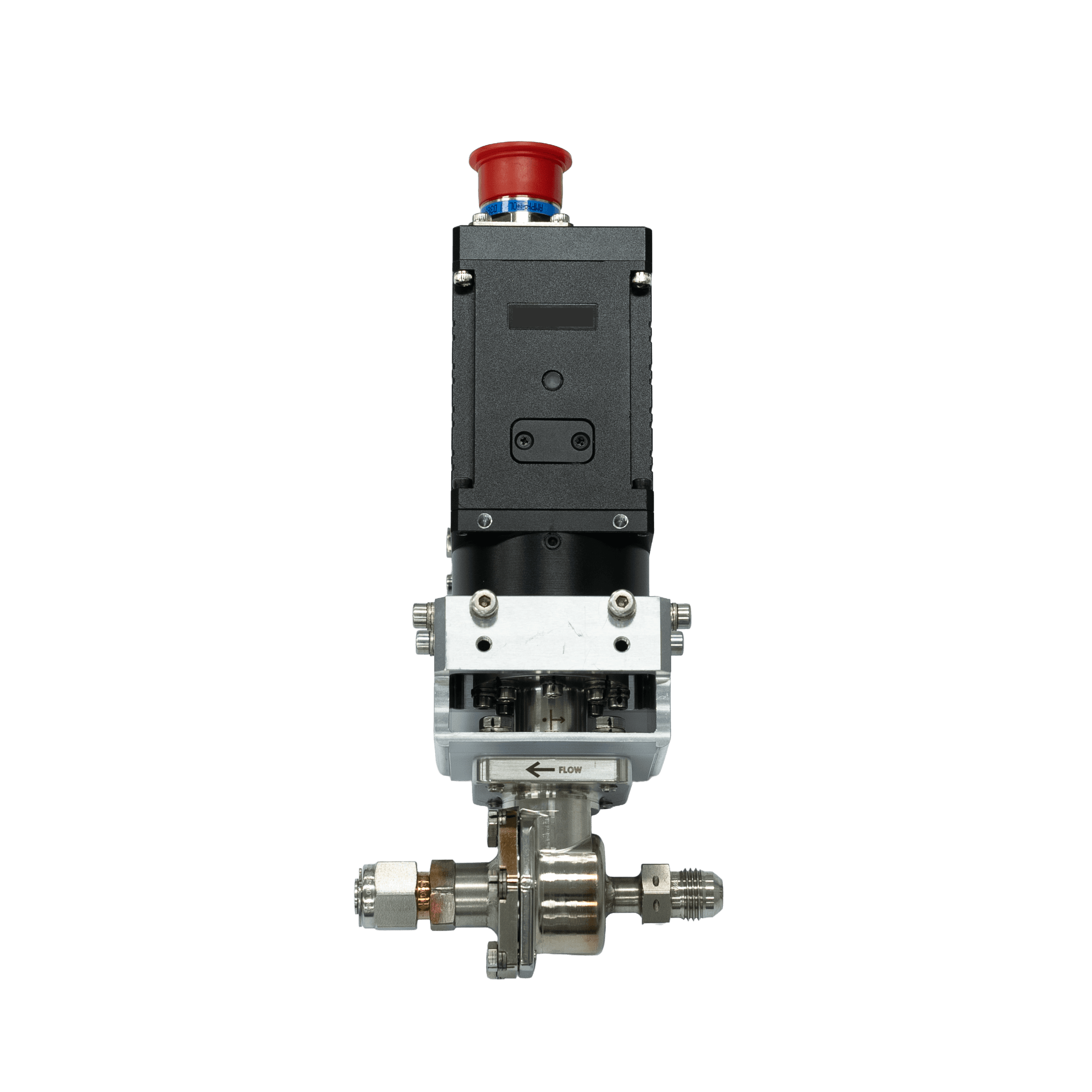

PGUV

PGUV was developed for the gas generator valve in the 3-ton gas generator cycle methane engine and for the combustor valve in the 1-ton pressure-fed cycle methane engine. It is currently in operation in combustion testing, powerpack testing, and suborbital vehicles. PGUV integrates flow control and on-off functionality and is a motor-controlled ball valve.

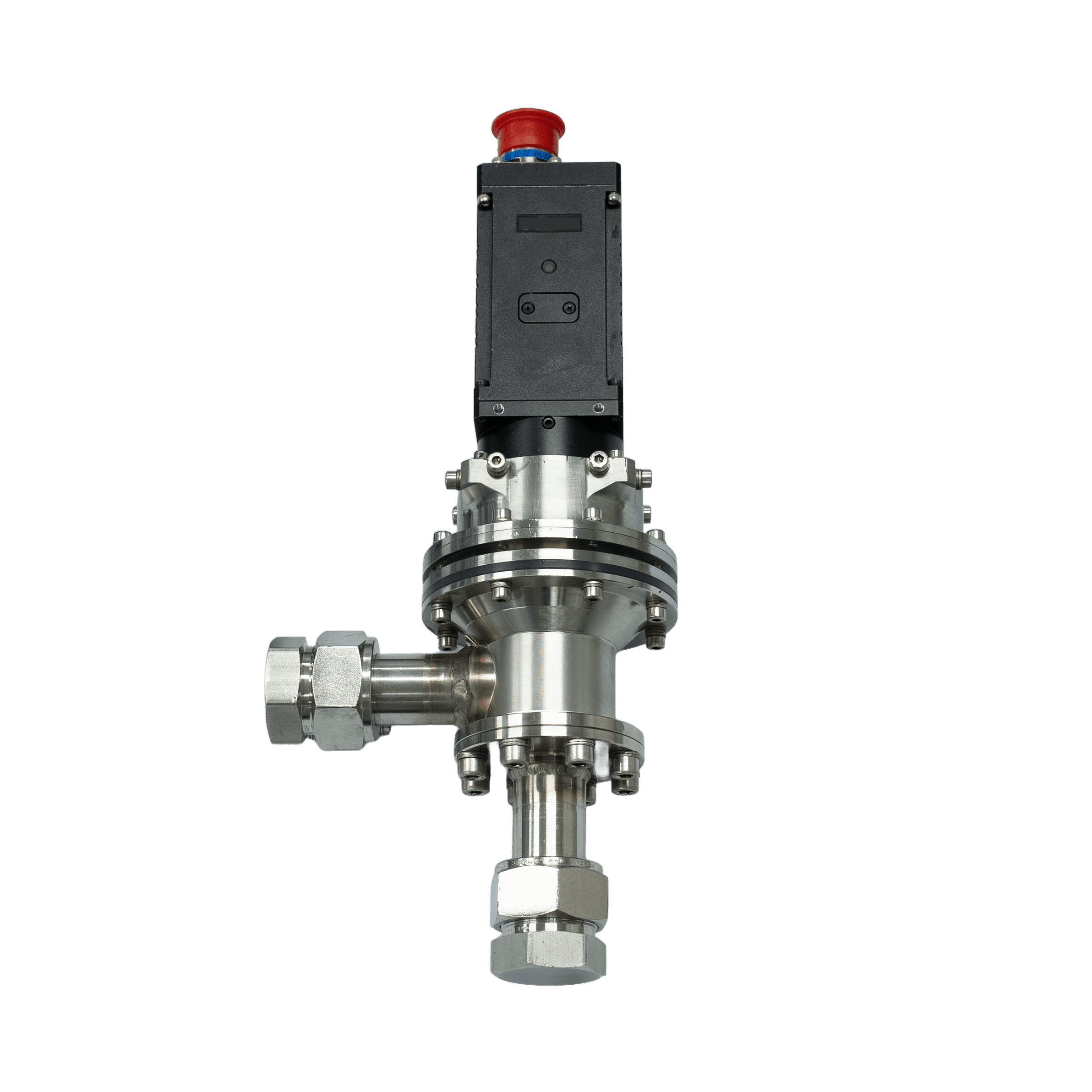

PMCV

PMCV was developed as the main combustion chamber valve for the 3-ton gas generator cycle methane engine and is currently used in powerpack testing. It integrates on/off and flow control functions and is a motor-controlled poppet valve.

PTSV

PTSV was developed as the turbine start and purge valve for the 3-ton gas generator cycle methane engine and is used in powerpack tests. It is a solenoid-type valve for high-pressure gas control.

PFTV

PFTV was developed as a flight termination valve for both the 3-ton gas generator cycle methane engine and the 1-ton pressure-fed methane engine. It is applied in suborbital test vehicles. Operated by a pyrotechnic igniter, it is available in both Normally Closed (NC) and Normally Open (NO) configurations.

Proven Performances

PGUV, PMCV, PTSV, and PFTV valves have been qualified according to the environmental test requirement of KSLV-II 3rd stage and Perigee utilizes PGUV, PMCV, PTSV and PFTV in combustion tests, powerpack tests, and other cryogenic/high-pressure testings.

High Reliability Under Extreme Conditions

All valves have passed strength, leakage, flow, lifecycle, and launch environmental tests in cryogenic and high-pressure conditions with LOX, LNG, LN2, and GN2.

In-house Development and Qualification

From design to production and testing, all processes are conducted in-house, with environmental qualification completed under KSLV-II flight standard.